Behind the Craft

Design

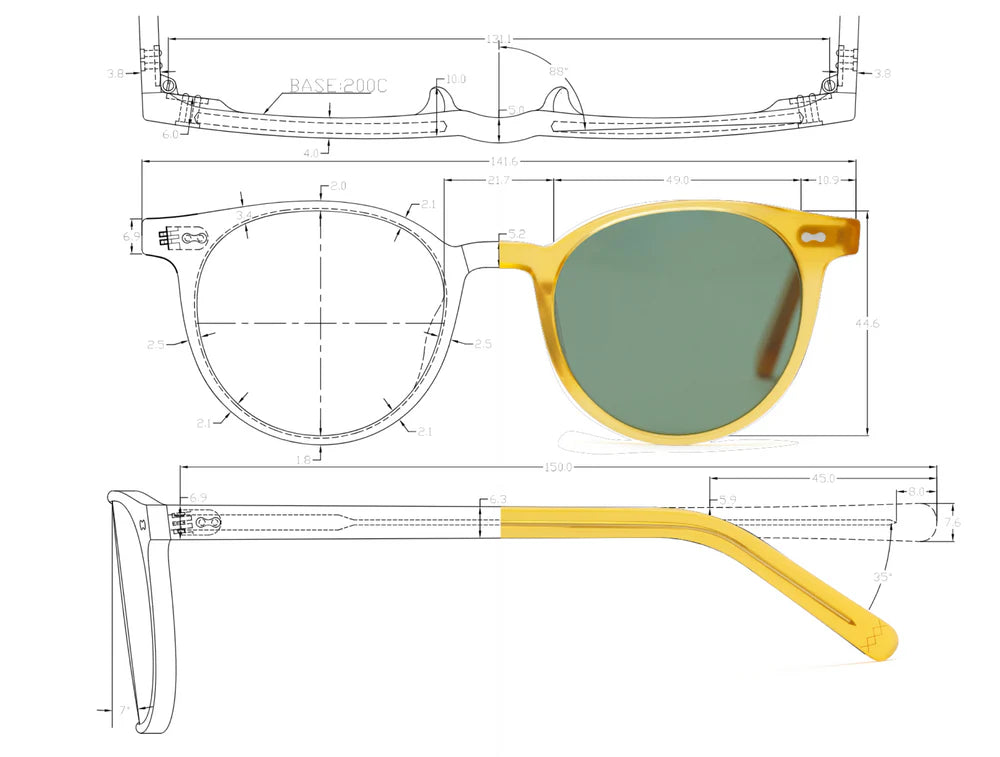

Each model is imagined and sketched in our Bali workshop. Once the drawing is validated, we select Mazzucchelli acetate sheets and pair them with the ideal lens tint.

Handmade Collection

Entirely handcrafted in our boutique workshop in Bali, each frame goes through a slow and precise process: 80 steps over 15 days, carried out by 3 artisans. Every acetate sheet is cut, shaped, bent, and polished by hand, then reinforced with metal cores inserted and sealed with heat. The polishing involves ten manual steps to bring out the full shine of the material. As a final touch, the name is engraved and hand-painted in the boutique.

Signature Collection

Our Signature Collection is produced in limited quantities: timeless frames that are easy to wear and built to last. Using natural materials and premium components, our glasses are made through three production channels in Italy, Germany, and China, in collaboration with renowned suppliers such as Mazzucchelli, Jinyu, and Jimei.

Packaging

Our cases and pouches are handcrafted in collaboration with local artisans. Leather cases are made in Kerobokan, woven pandanus cases in Yogyakarta (Java), and fabric pouches are sewn in Seminyak, Bali.

Assembly in our Canggu boutique

Each frame is first scanned for a precise lens cut. Lenses are then centered, their power verified, and adapted to the frame under the supervision of our optometrist. Final assembly and adjustments are completed directly in-store.

Manual Quality Control

Each frame undergoes a rigorous 20-point inspection, from fit to finish. Our team refines the polish if needed, while another technician independently checks the lenses for power and alignment. Once approved, the glasses are ready.