Dibalik Kerajinan

Desain

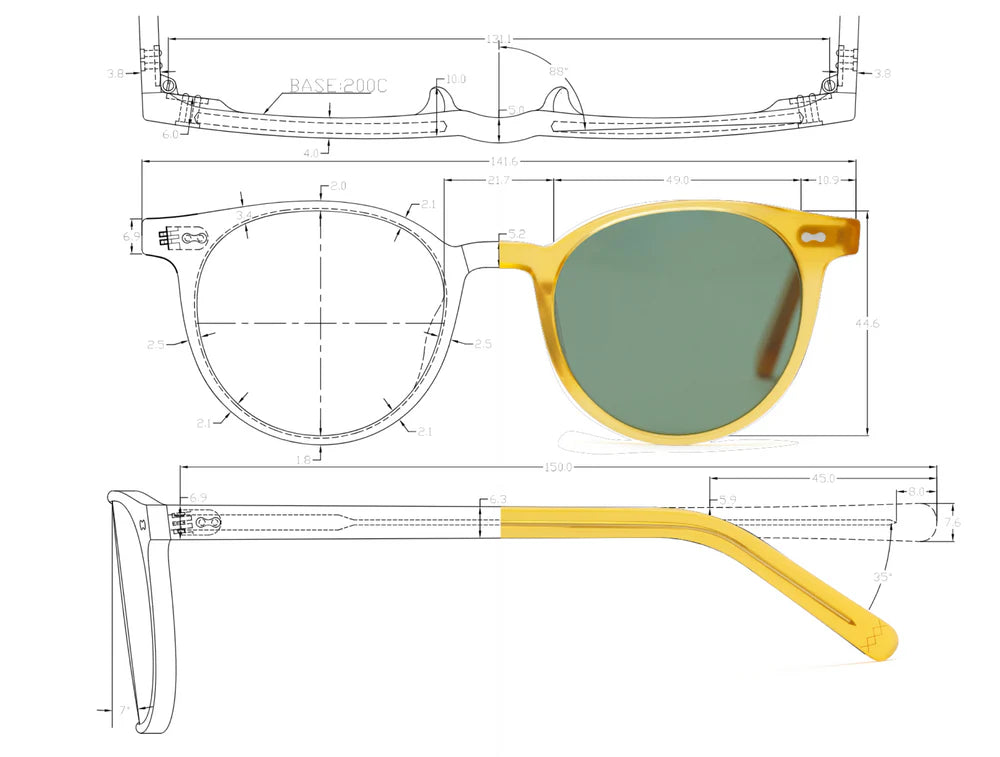

Setiap model dibayangkan dan digambar di workshop kami di Bali. Setelah desain disetujui, kami memilih lembaran asetat Mazzucchelli dan memadukannya dengan warna lensa yang sesuai.

Dibuat tangan di Canggu

Di workshop butik kami di Bali, setiap bingkai melalui proses yang lambat dan presisi: 80 langkah dalam 15 hari, dilakukan oleh tiga pengrajin. Setiap lembar asetat dipotong, dibentuk, dibengkokkan, dan dipoles secara manual, lalu diperkuat dengan inti logam yang disegel panas. Sentuhan akhir berupa ukiran dan pengecatan tangan langsung di butik.

Signature Collection

Our Signature Collection is produced in limited quantities: timeless frames that are easy to wear and built to last. Using natural materials and premium components, our glasses are made through three production channels in Italy, Germany, and China, in collaboration with renowned suppliers such as Mazzucchelli, Jinyu, and Jimei.

Packaging

Our cases and pouches are handcrafted in collaboration with local artisans. Leather cases are made in Kerobokan, woven pandanus cases in Yogyakarta (Java), and fabric pouches are sewn in Seminyak, Bali.

Assembly in our Canggu boutique

Each frame is first scanned for a precise lens cut. Lenses are then centered, their power verified, and adapted to the frame under the supervision of our optometrist. Final assembly and adjustments are completed directly in-store.

Manual Quality Control

Each frame undergoes a rigorous 20-point inspection, from fit to finish. Our team refines the polish if needed, while another technician independently checks the lenses for power and alignment. Once approved, the glasses are ready.